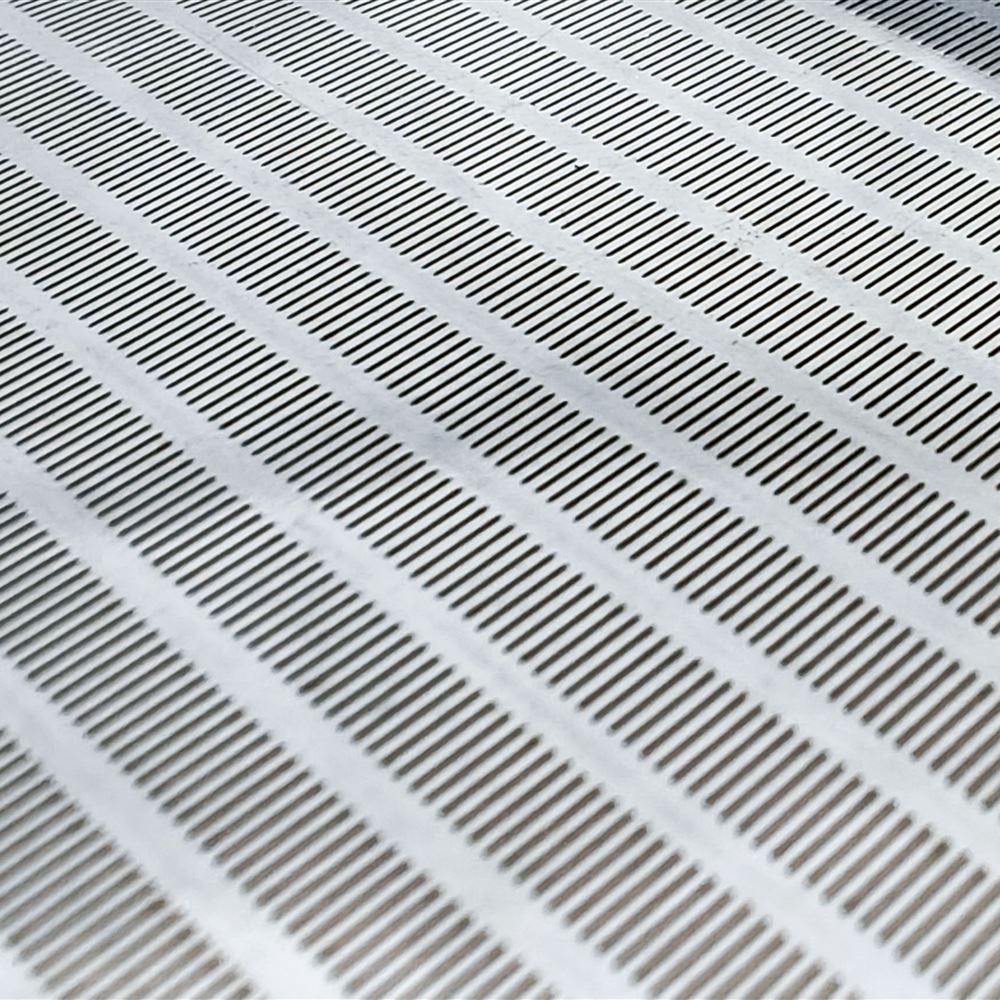

Laser stainless steel working screen for batch centrifuge

Through modernize, with laser cutting as the core high technology manufacturing processes, SU GROUP supply stainless steel screen for batch centrifuge users. The minimun width of offering working screen slot size can reach 0.1mm, it significantly improving crystal recovery rate, realize the best separation effect. Now, the continuous centrifuge of Su Group has been equipped with laser screen when delivered.

Advantage

- Made of stainless steel

- 1.5 times tensile strength than traditional nickel-chromium screen.

- More than 3 times service life than traditional nickel-chromium screen.

- High material recycle rate

Service and Purchase

- Service

- Purchase

- Download

About services:

To ensure your equipment continuously and efficiently operation, and to maximize the service life of the equipment, we offer comprehensive on-site training and professional after-sales service support. Our services targetis to help your operation team in-depth understand equipment functions and maintenance requirements, ensuring that every section of the production process is in most optimized status.

+86 771 4019108 / 4018700

+86 771 4019108 / 4018700 info@sugroup.cn

info@sugroup.cn